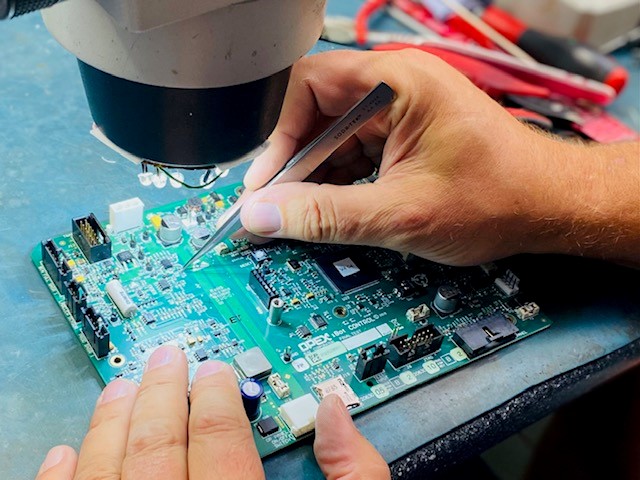

Because of its high demands, PCB electronic repair has been accurately compared to surgery, Some will need a stitch or two while others will need open heart surgery? To expect a reliable outcome, each repair project must follow proven and well established procedures!

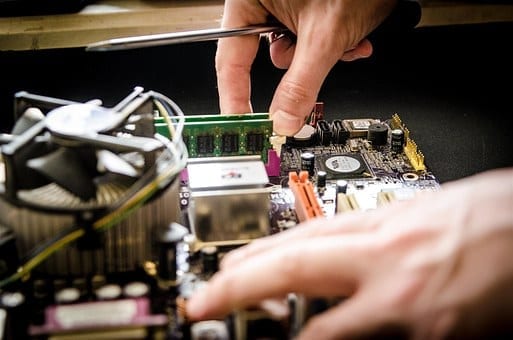

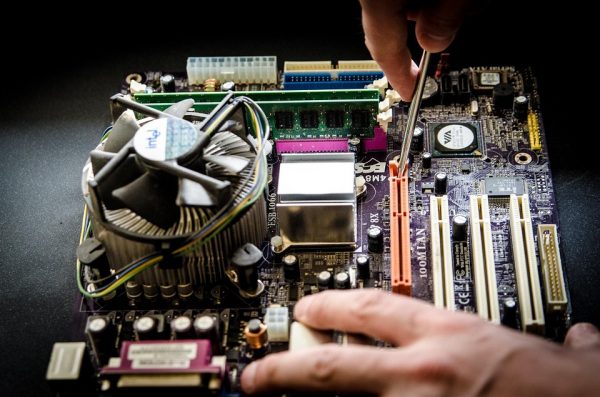

Whether replacing surface mount devices or repairing damaged internal circuitry, Greasley’s repair technician’s have the technical knowledge and manual skills needed for high reliability repair and rework, the repair specialists are experts and have repaired thousands of PCB boards!

Since today’s circuit board repair procedures are more sophisticated than ever before, we use the very latest procedures and technology, we are able to offer PCB Modification and final test and assembly.

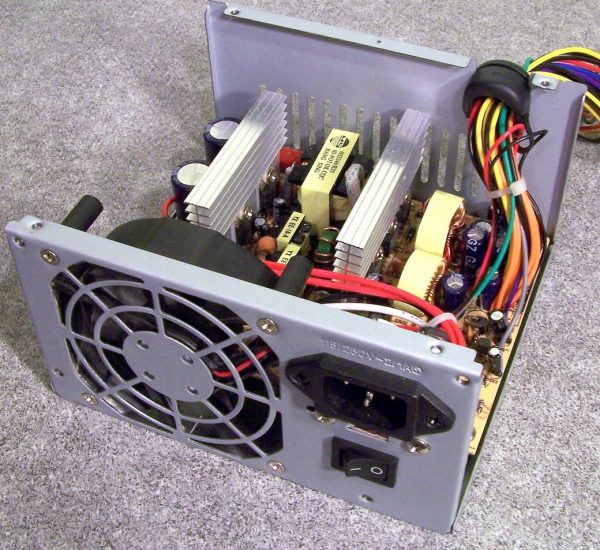

In April 2022 we invested in a new BGA (Ball Grid Array) Rework and Reballing Machine. This semi-automatic system easily handles small or large printed circuit boards.

New BGA Machine installed at Greasley Electronics

Innovative technologies such as high-resolution camera placement, hybrid heating using infrared and convection, and the intuitive software ensure repeatable component alignment and automatic soldering, thus minimizing operator reliance. It is configured for residual solder removal and dispensing of flux or solder paste.

Guy and Stuart impressed by the machine!

Once calibrated, this machine has the ability to set endless templates and with hot gas, facilitates the reliable and precise rework. It uses an automated system to pick and place almost any component and has 99.9% accuracy. John Rawlings, Managing Director, and the Greasley team are delighted with it and enables us to provide pcb repair and refurbishment to the next level.

When manufacturers are buying machinery into the UK with repairs that they think cannot be repaired, Greasley Electronics can be on hand with their expertise and fully trained engineers.

For more information on our BGA Machine, click here.

.